Galvanized Wire Mesh – Woven, Twisted and Welded Wire Fabric

Galvanized wire mesh refers to the surface of the steel wire fabric is coated with a zinc layer to protect the mesh from corrosion.

The galvanizing process was invented in the middle of the 18th century, and it was developed from the tinning process. So far, galvanizing is still the most commonly used and most effective process measure in steel corrosion protection methods.

Types of Galvanized Wire Mesh

Galvanized wire mesh is mainly divided into the following types according to the production method:

- Galvanized woven wire mesh

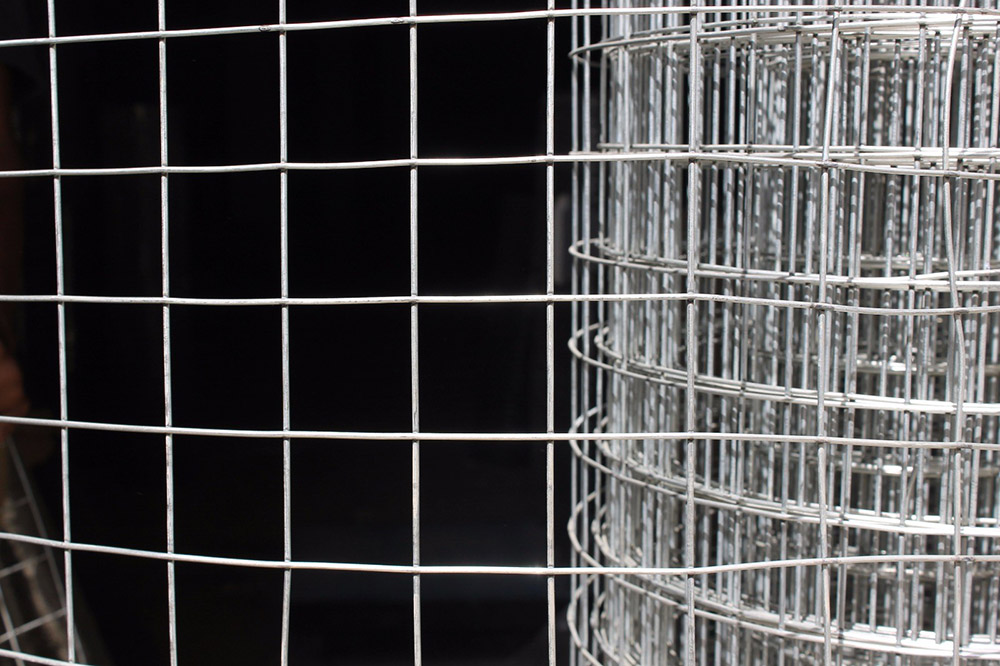

- Galvanized welded wire mesh (welded wire fabric)

- Galvanized twisted wire mesh (also known as chicken wire)

- Galvanized chain-link mesh

Galvanization Technology

Galvanizing technology is generally divided into two types: electro-galvanizing and hot-dip galvanizing.

- Electro-galvanized wire fabric: also called cold galvanizing. It uses electrolytic equipment to put the wire or wire fabric into a solution containing zinc salt and connect the negative electrode of the electrolytic equipment. Place a zinc plate on the opposite side of the wire mesh, connect it to the positive electrode of the electrolysis device and turn on the power supply. The directional movement of the current from the positive electrode to the negative electrode will deposit a layer of zinc on the wire mesh.

- Hot-dip galvanized wire mesh: refers to putting the derusted wire mesh into a molten zinc pool, so that the surface of the wire mesh is coated with a zinc layer.

Galvanizing Method

There are two ways to galvanize steel wire mesh:

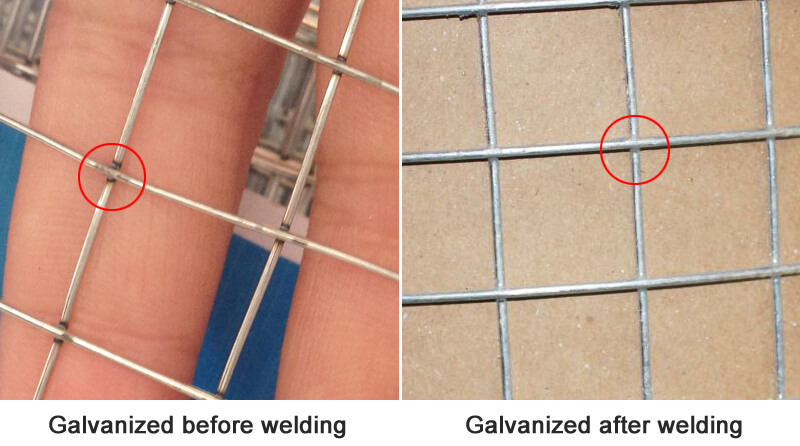

- Galvanize the wire before, then weave, twist or weld the wires into the mesh: This manufacturing method is relatively inexpensive, but the corrosion resistance is not as good as the latter, because the zinc layer of the warp and weft threads of the screen tends to be damaged during weaving or use, and it is easy to rust in a humid environment.

- Weave the ungalvanized wire before, then galvanize the whole mesh: The manufacturing cost is higher than the former, and the corrosion resistance is better, because the intersection of the warp and weft of the wire mesh is covered by a zinc layer.

Galvanized Wire Fabric vs Stainless Steel Wire Mesh

Both types of wire mesh have a wide range of uses such as hardware cloth, garden fence, plaster mesh, poultry fence, etc., the cost of galvanized material is much cheaper, but the rust resistance and service life are far inferior to stainless steel mesh. In addition, the stainless steel material such as AISI 304 (1.4301) and 316 (1.4401) can maintain a bright surface for a long time or even for a lifetime, while the galvanized material will gradually disappear after a period of use.