What is a Metal Mesh Sheet?

Metal mesh is a sheet metal with a series of openings. The most common openings are square, rectangular and round. Metal mesh plays an important role in industrial and commercial use. You can find it almost anywhere, such as hardware cloth, chicken wire, speaker grill, stainless steel or aluminum window screen, microwave oven mesh screen, garden metal fence, concrete mesh, etc.

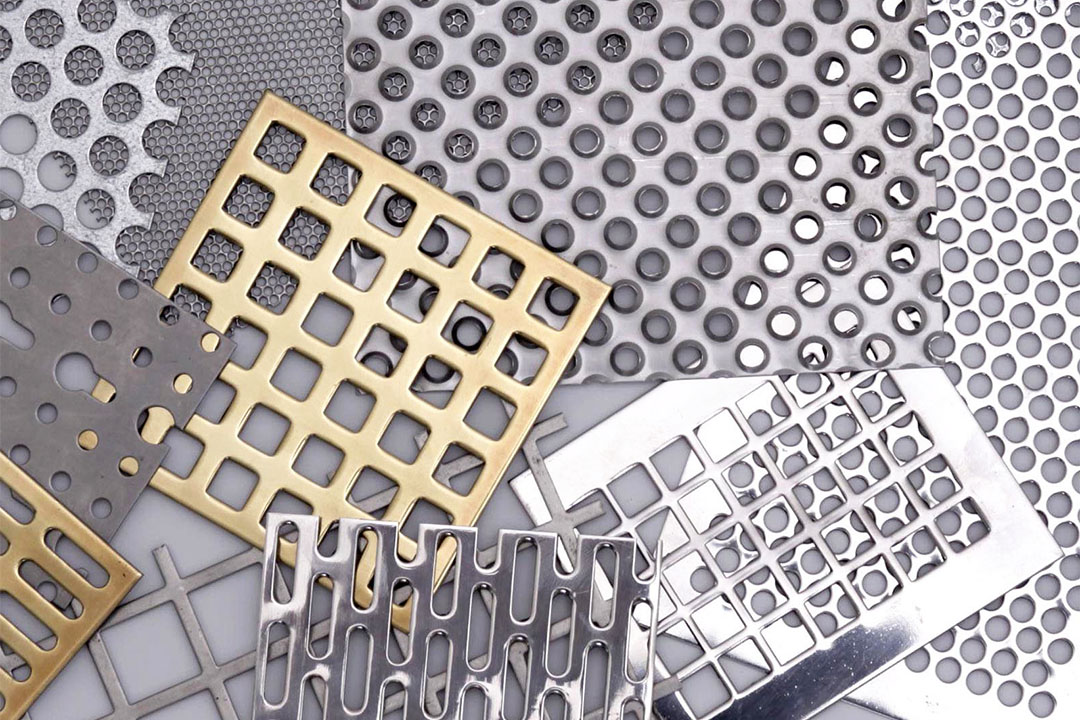

There are many types of metal mesh sheet, and the common classifications are as follows:

Types by Material

- Carbon steel mesh sheet: The lowest cost material, usually mild steel, such as S235JR, A36 steel, 1018, 1020, etc., and no surface treatment. The advantage is that the price is very cheap, the disadvantage is that the corrosion resistance is poor.

- Galvanized steel mesh sheet: It is coated with a layer of zinc on the surface of carbon steel to prevent corrosion.

- Stainless steel mesh sheet: Usually made of stainless steel 304, 316, 302 and 430, etc.

- Aluminum mesh: Made of aluminum alloy

- Copper mesh: Made of pure copper, with excellent electrical conductivity, thermal conductivity, electromagnetic shielding performance.

- Brass mesh: The copper alloy containing 65% copper and 35% zinc.

- Other alloy materials

Types by Manufacturing Method

- Woven mesh sheet is square opening mesh made by interweaving the metal wires of warp and weft with by a loom. Common weaving methods are plain weaving, twill weaving and Dutch weaving, and the mesh count range is 1-600 mesh per linear inch.

- Welded wire mesh sheet is a kind of grid metal. The parallel horizontal and vertical steel wires are firmly welded at the intersection of each steel wire by an electric welding machine. Its material is usually low-carbon steel or low-carbon stainless steel.

- Perforated metal sheet is a metal mesh in which sheet metal is perforated through a series of openings by a punch die of a specific shape.

- Expanded metal is a metal mesh sheet with diamond-shaped openings by cutting through a metal sheet or panel and expanding the cut with a series of horizontally arranged knives.

- Laser cut screen is a metal sheet mesh in which a series of patterns of characteristic shapes are cut on a metal sheet by a CNC laser cutting machine.

Types by Hole Shape

- Square hole

- Round hole

- Round-end slotted hole

- Decorative holes

Typical Applications of Metal Mesh Sheet

- Concrete mesh, essentially a weld mesh, used for building concrete and strengthening the building structure.

- Plaster mesh, used for the protection or decorative coating of walls and ceilings, available products include welded hardware cloth, chicken wire, expanded metal lath, etc.

- Filtering and sieving mesh, for precision or coarse filtration, such as filter element, metal coffee filter, tea filter, pleated filter, candle filter, etc.

- Hardware cloth, a metal mesh sheet or roll with a mesh opening of 1/4-1 inch.

- Fence mesh